The smart Trick of Conway Concrete Company Concrete Driveway That Nobody is Discussing

Wiki Article

The 2-Minute Rule for Conway Concrete Company Concreters

Table of ContentsConway Concrete Company Concrete Slab Fundamentals Explained6 Easy Facts About Conway Concrete Company Concrete Slab DescribedThe Greatest Guide To Conway Concrete Company Concrete Foundation3 Simple Techniques For Conway Concrete Company ConcretersThe Only Guide to Conway Concrete Company Concrete PatioThe Ultimate Guide To Conway Concrete Company Concrete Contractor

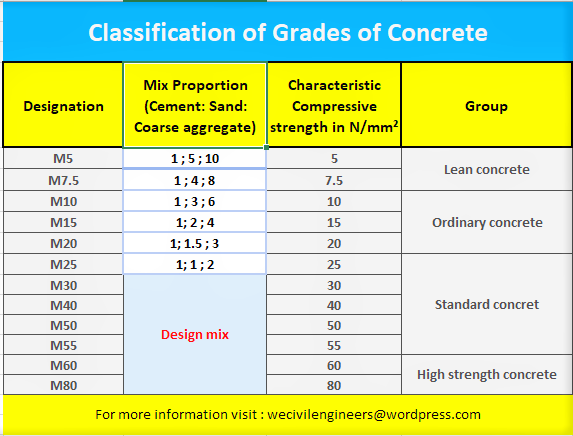

The components of concrete respond differently with each other based on the ratio of just how much of each is included, and percentages will certainly differ based upon the kind of concrete being made (Conway Concrete Company concrete contractor). One of the most typical proportion, nevertheless, is: 1015% cement6075% aggregate1520% water The concrete mixing process starts with preparing the Portland concrete mix.After the Portland cement is prepared, it is combined with the accumulations, water, as well as optional admixtures (the various chemicals or materials that alter the uniformity and stamina of concrete). The components are mixed with each other well, regarding effectively coat the aggregates with the concrete paste. After combining the materials, the concrete is triggered by the water, layer the accumulated bits and obtaining strength as it sets in a procedure called hydration.

There are several kinds of concrete, nonetheless, as well as they are used for all various sorts of frameworks - Conway Concrete Company concrete slab. Right here are 16 types of concrete as well as just how they are utilized. Regular toughness concrete, or "routine" concrete, is the most typical kind of concrete with a standard mix of cement, aggregates, and also water.

Concrete Driveway Can Be Fun For Anyone

Regular toughness concrete is generally used for sidewalks, residence building tasks, as well as structures that do not require optimal tensile toughness. Ordinary concrete is concrete in its most basic kind.

This kind of concrete has a reduced thickness as well as a greater water content than normal concrete. Light-weight concrete is made using light-weight aggregates, such as pumice, clay, or perlite. Considering that the details accumulations selected are what establishes the thickness of the concrete, light-weight concrete is low in thickness, as well as is defined as any kind of kind of concrete with a density degree of less than 1920kg/m3.

All set mix concrete is made at a manufacturing plant as well as delivered to a construction website making use of an associate a mixer connected to it. It typically has admixtures to make it so the concrete does not solidify before arriving at the website, and prepares to pour. Polymer concrete is concrete in which the lime as well as shale-based Portland concrete is changed with a polymer binder that cures and hardens, such as a polyester, epoxy mixes, plastic ester, polymers, or several numerous kinds of polymer materials.

The Best Strategy To Use For Conway Concrete Company Concrete Foundation

Epoxy binders, as an example, will aid in less shrinkage throughout healing while acrylic binders offer weather condition resistance and also quicker setup times. Polymer plastic is stickier than cement, and also therefore, when combined in a concrete mix, results in a concrete of higher tensile stamina than one composed of Rose city cement. When blending with each check this site out other a polymer binder with water as well as aggregates, a chemical response happens that starts the treating process quicker than routine concrete.Concrete is described as glass concrete when recycled glass is included as an accumulation, or utilized in locations of both great and coarse accumulations, relying on the preferred outcome. Glass aggregates are usually made from recycled glass as well as can vary in dimension from a great talc-like powder to gravel-side pieces to six-inch glass rocks.

Glass concrete usually has a shiny or "radiant" aim to it, that makes it a visually pleasing as well as extremely polished looking alternative for counter tops, floors, as well as tiles. Enhanced concrete, also referred to as strengthened cement concrete, is made with strengthened bars, usually rebar, to boost the tensile stamina of the concrete.

Some Known Details About Conway Concrete Company Concrete Slab

Contractors could come across reinforced concrete in massive structures that require an enormous quantity of tensile stamina, such as high buildings, bridges, dams, or any type of construction situation that entails a structure requiring to lug incredibly hefty lots. Concrete is the most prominent building material worldwide. It's the second most made use of product in the globe (water reigns supreme at number one).Concrete is durable because it does not rust, rot, or burn. The use of concrete as a building product is necessary to structures as a result of its toughness, stamina, and also severe long life. The standard residential or commercial properties of concrete are great and coarse aggregates (like sand and also rocks or pebbles), Rose city concrete, as well as water.

When Rose city cement as well as water incorporate, a chemical reaction called hydration occurs. Through this procedure, the paste layers the accumulations and also bonds them with each other, acquiring toughness as it solidifies, and concrete is created. When making concrete, contractors use great accumulation to include quantity, while rugged aggregate supplies the stamina needed to bring heavy tons.

How Conway Concrete Company Concrete Driveway can Save You Time, Stress, and Money.

Before concrete is made, the 3 raw materials should be go to website proportioned appropriately to ensure the outcome of a blend that is strong and tough. The elements of concrete respond in different ways with each various other based on the proportion of just how much of each is added, as well as proportions will certainly vary based on the sort of concrete being made.

Rose city concrete is made of a calcareous product (commonly limestone) that is ground up right into a powder, which is then warmed as well as burned in a rotating, turning it right into a pebble-like material called "clinker" The clinker is after that ground up again until it is a smashed powder, to which plaster is added.

The active ingredients are stirred with each other well, as to properly layer the accumulations with the cement paste. After incorporating the products, the concrete is activated by the water, layer the aggregate fragments and acquiring toughness as it hardens in a process called hydration. Among the factors concrete is utilized to construct numerous various frameworks is due to exactly how functional it is and just how it can be molded to any type of wanted shape or layout.

The Greatest Guide To Conway Concrete Company Concrete Driveway

Here are 16 sorts of concrete and also just how they are utilized - concrete contractor. Normal stamina concrete, or "normal" concrete, is the most common type of concrete with a fundamental mix of concrete, aggregates, and water. Normal concrete has a increte concrete stamps for sale blending proportion of 1:2:4 (one component cement, 2 parts aggregate, four parts water), nonetheless, the amount of water used will depend upon the moisture of the area and also the desired consistency of the concrete.Report this wiki page